There are several types of aluminum used in the manufacturing process, the 6 series are the common one we used mostly, such as 6061-T6 aluminum, 6063 -T5 aluminum, which are the most commonly used material for structural components, especially in applications where strength , stability and corrosion resistance are the most important factors in projects. They both have excellent weldability, moderate machining and grinding capabilities, poor bending and forming capabilities, and also moderate wear resistance.

Nominal Chemical Composition

Alloying Elements | Mn | Fe | Mg | Si | Cu | Zn | Ti | Cr | Other (Each) | Others (Total) | Others (Total) |

Alloy 6061-T6 | 0.0 – 0.15% | 0.0 – 0.70% | 0.8 – 1.20% | 0.40 – 0.80% | 0.15 – 0.40% | 0.0 – 0.25% | 0.0 – 0.15% | 0.04 – 0.35% | 0.0 – 0.05% | 0.0 – 0.15% | Balance |

Alloy 6063-T5 | 0.0 – 0.10% | 0.0 – 0.35% | 0.45 – 0.90% | 0.20 – 0.60% | 0.0 – 0.10% | 0.0 – 0.10% | 0.0 – 0.10% | 0.0 – 0.10% | 0.0 – 0.05% | 0.0 – 0.15% | Balance |

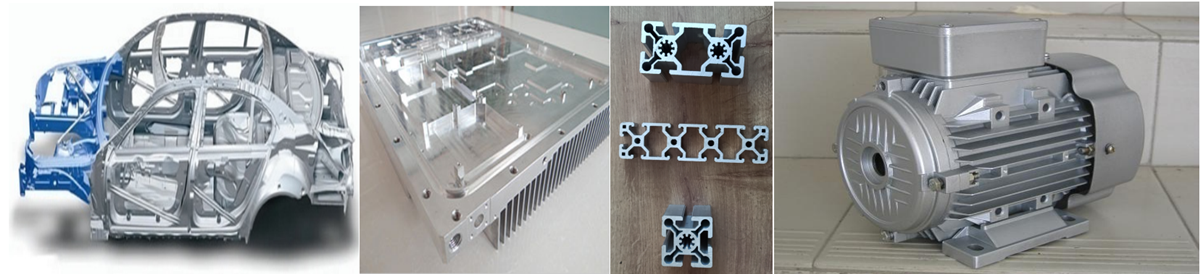

Comparing 6061 aluminum and 6063 aluminum, they appear very similar in characteristics. Due to their material strength and lightweight construction, these components are suitable for use in structural and general engineering and manufacturing applications across a wide range of industries, including transportation, building, construction and industrial applications as well as other relevant further fabricated products. When for applications in which higher strength and a finer finish needed, 6063 may be a more suitable choice.

Mechanical Properties

Aluminum type | Alloy 6061-T6 | Alloy 6063-T5 |

Tensile strength | 124-290 MPa | 145–186 MPa |

Yield strength | 276 MPa/40000 psi | 214 MPa/31000 psi |

Fatigue strength | 96.5 MPa/14000 psi | 68.9 MPa/10000 psi |

Hardness (Brinell) | 95 | 73 |

Machinability | Good | Fair |

Thermal conductivity | 151-202 W/(m·K) | 201-218 W/(m·K) |

Whether used for standard aluminum manufacturing or custom aluminum extruded metalworks, JLT extruded aluminium profiles system would be applied in the most flexible and economical manner. We offer design, fabrication, and finishing services to our customers by providing the specific extruded part or components as required. We strive to fight in the development of the most applications.